We go inside a MRF to learn where our recycling goes!

by Karin

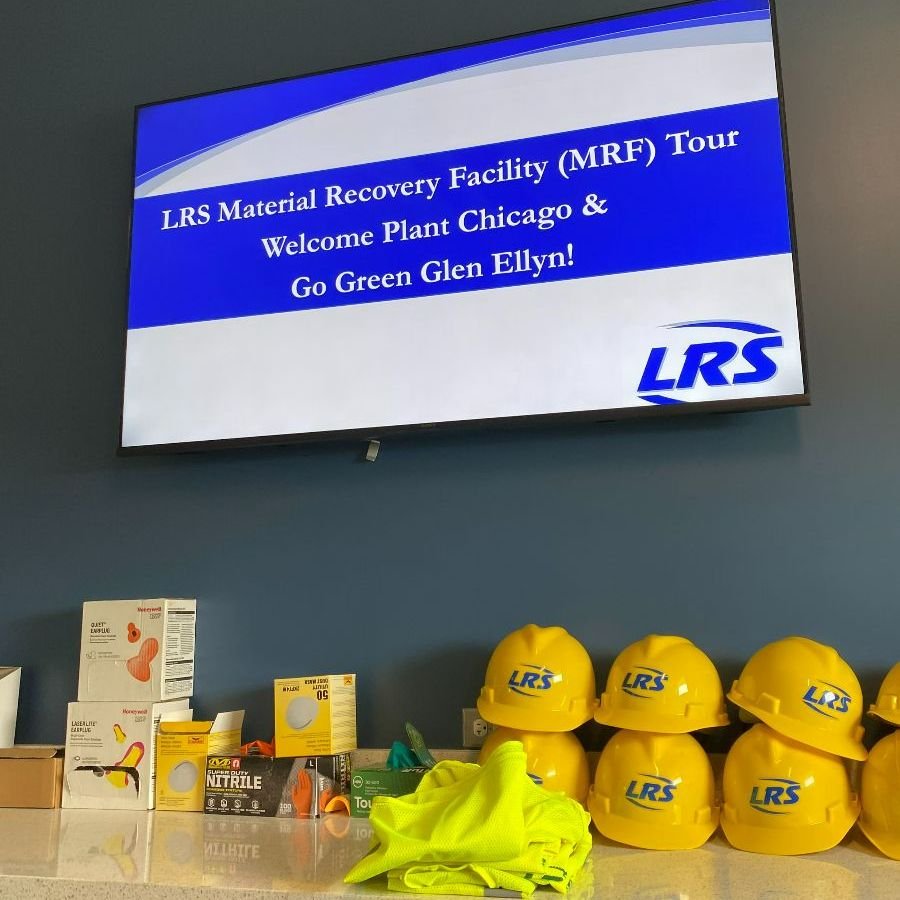

Ever wonder what happens after your recyclables go into the bin on trash day? Does it all get recycled? We were curious too. And that meant: FIELD TRIP! Go Green Glen Ellyn ventured to a state-of-the-art recycling plant in the former stockyards area of Chicago, also known in the business as a Materials Recovery Facility (MRF-- pronounced "murf.") We'll share some photos and what we learned there.

What goes on at a MRF?

A Material Recovery Facility (MRF) is a specialized facility designed to sort, process, and prepare recyclable materials for reuse. It serves as the link between your recycling bin and the manufacturing of new products from recycled materials. This particular MRF is owned by Lakeshore Recycling Systems (LRS) and Go Green Glen Ellyn got a sneak peak prior to the official opening of the $50M facility this week.

Safety First! We received a thorough safety briefing and donned our PPE which included hardhats, safety vests, goggles, earplugs and masks. The smell was not pleasant, but we acclimated quickly. We did notice that the plastic #2 bundles -- made from flattened laundry detergent bottles -- was the only area that smelled April Fresh! It is a loud and fast environment, with glass breaking into bins, cans flying by on conveyer belts, and workers swiftly moving between belts and machines.

The Sorting. MRFs play a pivotal role in maximizing the efficiency of recycling by sorting various materials such as paper, plastics, metals, and glass into separate streams. Trucks bring their haul directly to the facility where it is off loaded and the sorting begins!

Primary Sorting: Recyclables are unloaded and placed on a conveyor belt. Workers remove large non-recyclable items to protect the machines. One of the biggest issues are plastic bags as they truly gum up the works by getting tangled in equipment. Large items (we saw a shopping cart!) are also removed at this stage.

Machine Sorting: Next, the materials pass through a series of automated machines for additional sorting. These machines use robotic arms, chemical sensors, magnets, and vacuum/air jets to identify and separate recyclable products. Paper gets sucked up in one area, and a large magnet picks up metal. The "cleaner" that a stream can be (meaning similar materials sorted together not contaminated by other products) the more valuable that stream is for reselling.

Manual Sorting: Humans are still needed in the process. We saw quick hands grabbing items that had erroneously passed through the mechanical sorting. We were told that robotic machines are getting better and better, but that they still had a difficult time beating a trained worker on some items. Manual sorting can be dangerous for workers because items like needles, broken glass, dirty diapers and all other sorts of no-nos get put into recycling. Eventually, the goal would be to have the robotic arms take the place of some of the more hazardous sorting aspects, allowing humans to take different roles in the MRF.

Pop Art. Once sorted, the materials are compacted into bales for transportation to their next destination. Seeing rows of bales made up of compacted cans, milk jugs and detergent containers look almost like art, but also make you very aware of our consumptive society! You can see Jac and Karin in front of some of the bales in the picture below.

Show me the Money. We also had an interesting discussion about how a MRF makes money. First, they get some of their revenue from a municipality or business to provide bins and hauling. After sorting and processing the recycling (the facility, workers and equipment are pricey!), the MRF is able to sell the resulting material to a middle man, or directly to manufacturers. Each type of material has its own marketplace - different types of plastics, glass, paper, etc -- and each fluctuates, sometimes dramatically. For example, they mentioned that in the past few years, recycled cardboard was sold at a premium-- driven by the pandemic when we were all shopping remotely. But then demand shifted and it became difficult to find a buyer. When this happens, the MRF might only break even or take a small loss on the material. Regardless, they need to find buyers quickly as trucks arrive continuously with more material to sort and sell and there is only so much room.

Plastic Awareness

Plastics are a popular topic here at Go Green: Can't live with it, can't live without it. Plastic and its aftermath was a key issue of our time at the MRF (here is a short video explainer and a great interactive website from the UN). Our plastic consumption was one of the sobering things we witnessed (stacked in mountains around us!) and discussed on this visit. We were fascinated by the machines that could instantly detect the chemical composition of the plastic resin to sort by number. The recyclability of plastics depends on the resin type (what we see as a number on the bottom of a plastic piece). Only certain types are easily recyclable or valuable in the aftermarket. According to LRS, #2, and particularly clear milk jugs have the best aftermarket uptake. Oh, we could go on....and have!

We left with the reassurance that most of the what we put in the recycle bin does indeed get recycled. LRS says about 85% of what they receive ends up being processed, sold and reused in some capacity. Still, the more that we can do to reduce the amount we consume of single use plastics before it ends up at a MRF, the better our world will be!

We love digging in to a subject. Have a topic you'd like us to cover? Email us at gogreenglenellyn@gmail.com!